Wednesday, October 16, 2024

Tribotics Ltd, a leading provider of specialized detection and conveyor systems, embarked on a significant project with a major international retailer—Amazon. The project aimed to develop and implement a custom metal detection system specifically designed to enhance the safety and efficiency of Amazon’s cardboard waste handling process. With the rise of e-commerce and the increased volume of products flowing through fulfilment and distribution centres, there was a critical need to mitigate the risks associated with lost inventory and dangerous materials such as lithium-ion batteries entering the compactors.

Our solution was a large aperture conveyor-based metal detection system, specifically engineered to detect and reject items like batteries and lost electronics from the cardboard waste stream before entering the compactors. The solution focused on addressing two main concerns:

- Preventing potentially hazardous lithium-ion batteries from entering the compactor system, which posed a serious fire risk.

- Reducing Amazon’s stock loss by recovering valuable electronics that had been mistakenly placed in the waste stream.

Key Stakeholders and Collaboration

This project was a collaborative effort involving several prominent logistics and automation companies. Together, these companies worked closely with Tribotics Ltd to ensure seamless integration of our metal detection system within Amazon’s existing infrastructure.

System Development and Implementation

The metal detection system integrated a metal detector into a custom-built conveyor system, designed specifically for bulk cardboard handling. The system was tailored to Amazon's requirements and placed near the cardboard compactor to catch any unwanted metallic materials before they could enter the waste stream.

Key Features of the System:

- Metal Detection: The system is capable of detecting and rejecting batteries, preventing hazardous items such as lithium-ion batteries from entering the compactor.

- Custom Conveyor Design: The conveyor system was designed and built to handle a high throughput of bulk cardboard and integrate seamlessly with Amazon's cardboard compactors.

- Stock Loss Reduction: By detecting lost electronics (phones, tablets, etc.), the system helps prevent costly stock loss for Amazon, recovering these items before they are destroyed.

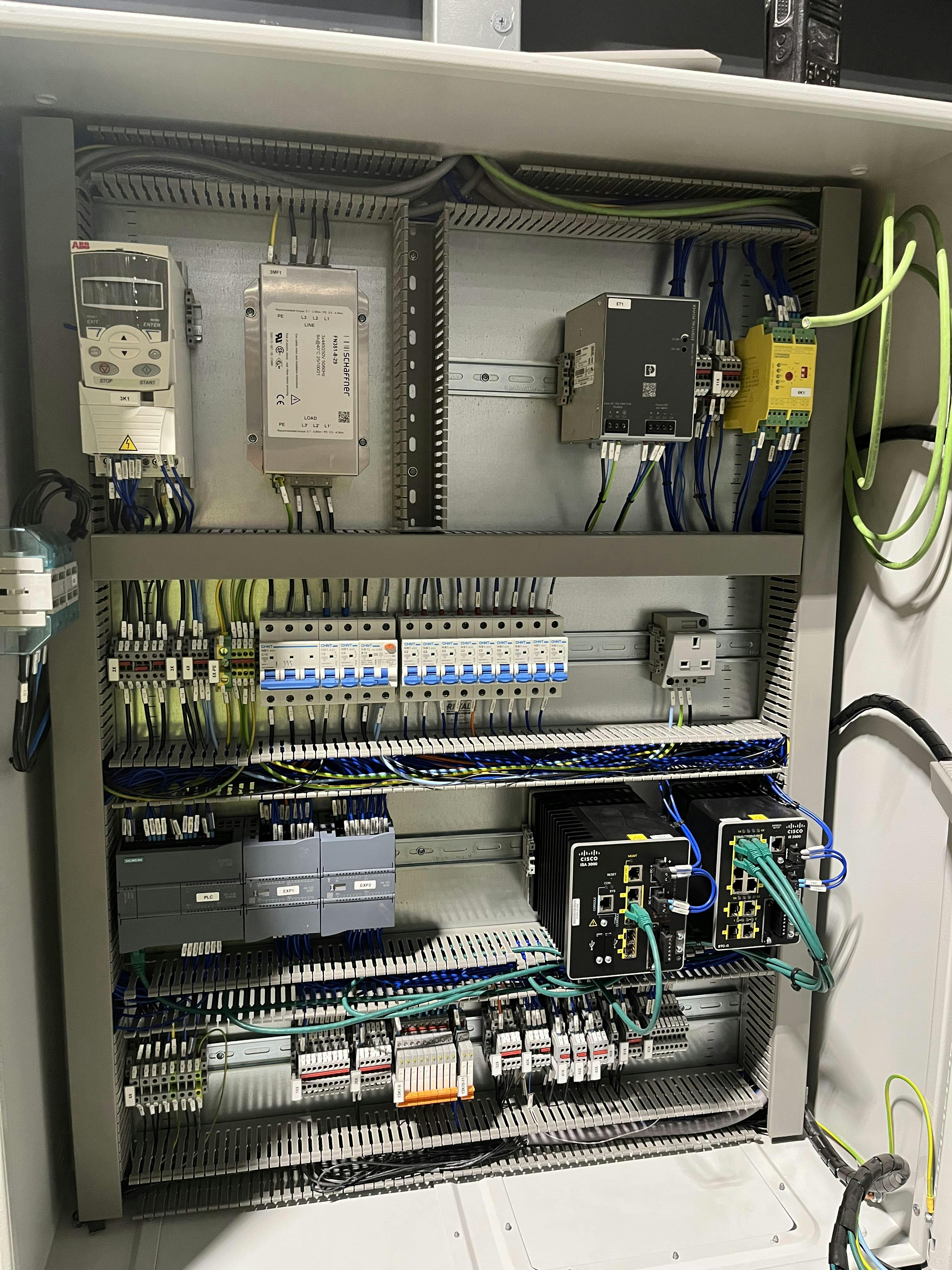

The system was developed using industry-standard control and communication equipment:

- Siemens PLC/HMI for system control and monitoring.

- Cisco Ethernet switches for robust network connectivity.

- ABB Variable Speed Drives to control the speed of the conveyor system for optimal performance.

Since the beginning of this partnership in 2018, Tribotics Ltd has installed over 200 metal detection systems to date, in Amazon warehouses across the UK, Europe and Australia.

Results and Impact

- Safety Improvement: The detection system effectively reduces the risk of fires by preventing lithium-ion batteries from entering the compactors, which could potentially combust under pressure. This safety feature has become a critical component in managing waste in high-volume fulfilment centres.

- Reduction in Stock Loss: By capturing lost electronics before they reach the compactor, the system has helped Amazon save significant amounts of stock that would otherwise be destroyed. This has led to reduced financial losses and improved inventory control.

- Operational Efficiency: The metal detection systems have been seamlessly integrated into Amazon's fast-paced fulfilment centres, ensuring minimal disruption to the flow of materials. The systems are designed for easy operation and maintenance, with minimal downtime.

- Expansion Across Europe: The success of the system in Amazon’s UK operations has led to its implementation in other European warehouses and a growing interest from other major retailers.

Ongoing Support and Customization

To ensure that the metal detection systems continue to operate at peak performance, Tribotics Ltd offers comprehensive support and servicing packages. These packages include:

- Routine Maintenance: Regular check-ups and servicing to detect any issues before they escalate.

- System Modifications: As customer needs evolve, we provide system upgrades or modifications to meet new business requirements, such as handling different types of materials or adapting to changes in warehouse infrastructure.

Conclusion

The partnership between Tribotics Ltd and Amazon highlights how custom-designed solutions can enhance safety, operational efficiency, and cost savings for large fulfilment and distribution centres. The successful deployment of over 200 metal detection systems to date, in Amazon warehouses across the UK, Europe and Australia, has not only safeguarded Amazon’s compactor systems from hazardous materials but also reduced stock loss, contributing to more sustainable and efficient waste management processes.

With ongoing support, service, and the ability to adapt to changing needs, Tribotics Ltd continues to deliver innovative solutions for some of the world’s largest retailers, helping them stay ahead in an increasingly competitive market.

For more information on our metal detection systems or to discuss how Tribotics can support your business, please contact us at sales@Tribotics.co.uk